X-Ray Inspection: Fast and Safe

Welding is a process through which the union of two solid parts is achieved, thus obtaining a single body. The operation is realized through the melting of the ends of the individual components, with or without the addition of further material.

It is a delicate maneuver and, for this reason, it presents potential margins of error and defects, such as porosity, cracks, tears, or geometric imperfections; obviously, the first weak point is where the parts have been joined, which is therefore the area to be tested with more attention.

Therefore, it is necessary to pay particular attention to quality control, before, during, and after welding, to ensure high safety standards and prevent dangerous breakages.

Where Metallurgy Meets Technology Today

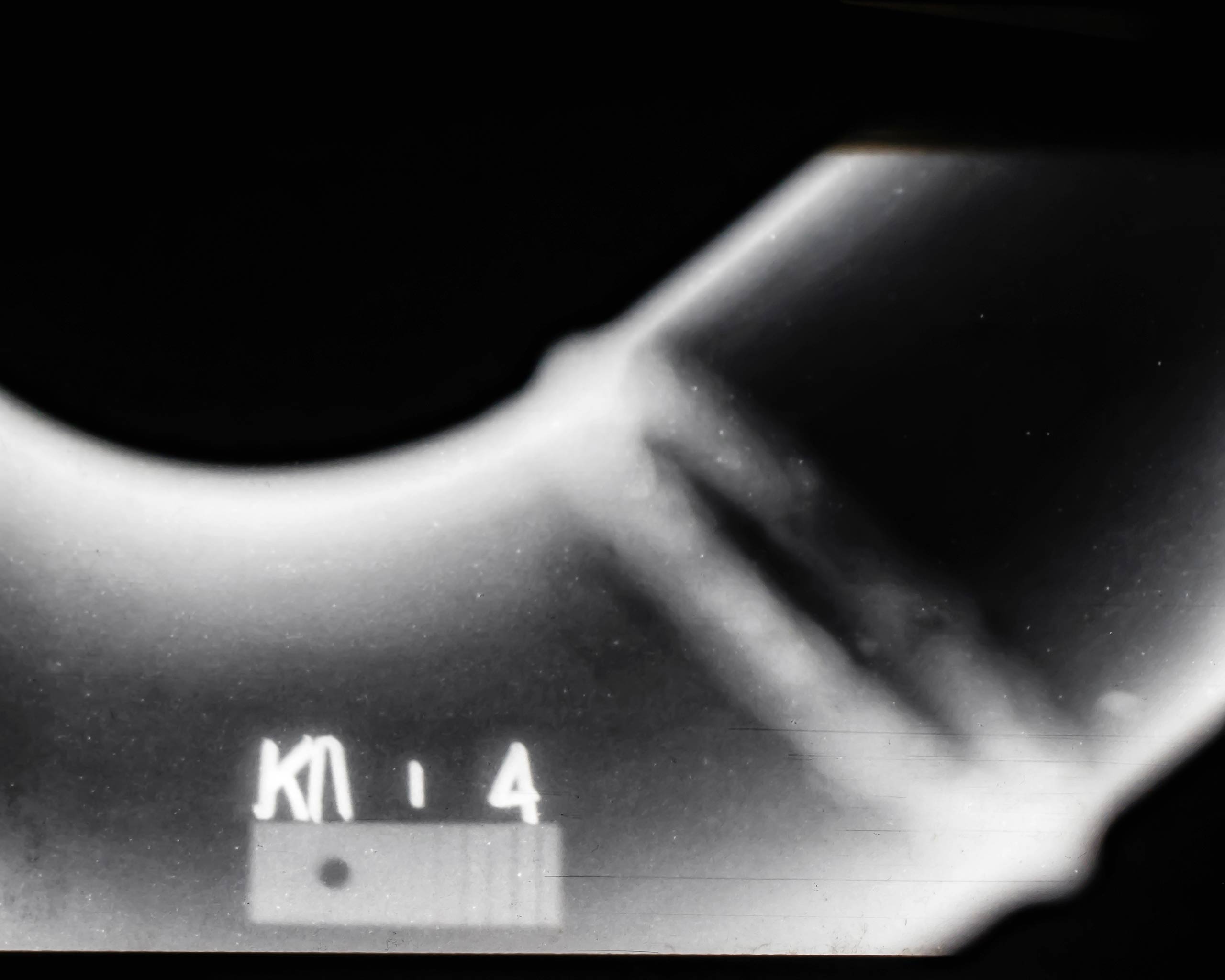

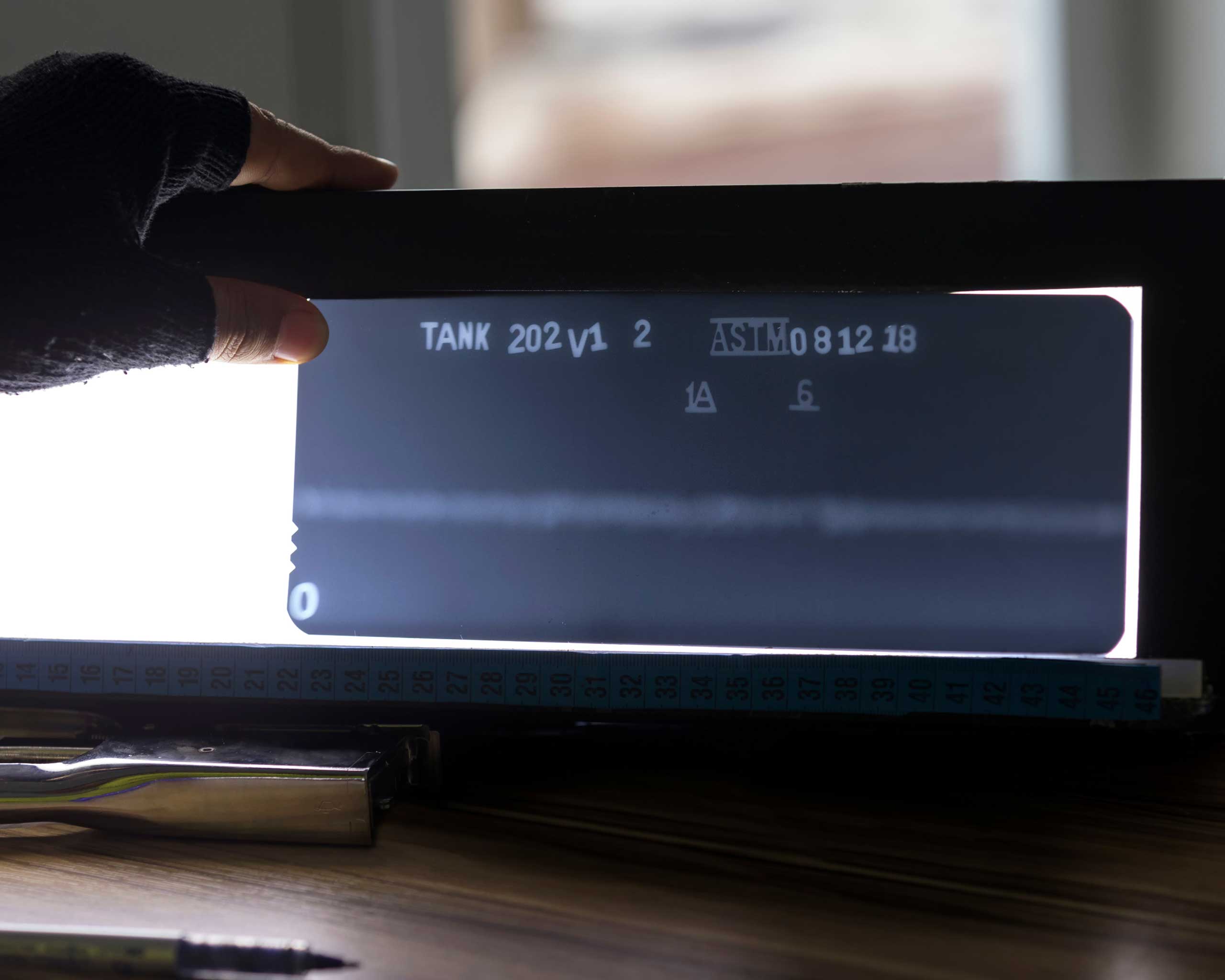

Specifically, among the various options available for post-welding verification, of fundamental importance is the technique through digital radiographic control, known as RT. This is a latest-generation methodology (replacing analog radiography, still in use but decidedly more obsolete). This technique falls into the category of non-destructive testing (NDT), meaning it does not damage or modify the structures being examined.

The RT examination allows for immediate (we are talking about visualization waits of a few seconds) digital radiography of the weld at very high resolution. Achieving such a level of image quality is possible thanks to the use of special sensors, which operate in magnification and a system of hardware and software that detects the signal, translating it into an image on a monitor.

This technique is highly appreciated because it allows for the revelation of all types of potential imperfections, but only on the condition that the radiography is carried out in compliance with very specific standards (such as, for example, the position of the beam with respect to the area to be examined). The parameters to be observed in the execution of a radiography are called Quality Indicators, and in Italy, such rules are grouped in a regulation defined as UNI.

Through radiographic examination, not only can any imperfections in the welding be identified, but also classify its purity according to quality classes, also dictated by the UNI EN ISO 383 standard.

Service and Quality Standards, Let’s See Them Together

The UNI EN ISO 3834 standard defines the quality criteria to be followed regarding the welding of materials, to be respected both by those who make them and by those who check them later. This regulation concerns all activities related to welding, regardless of the final product to be obtained and the production sector in which we find ourselves. In essence, a certification attesting that the welding carried out is up to standard must be obtained.

Following the rules imposed by this regulation, the control through radiography is applicable only in cases where the materials in question are simple geometries and with certain thickness limits, namely a maximum of 180 mm.

The option of employing the radiographic technique, compared to other non-destructive control methods, offers 4 competitive advantages:

- It can be used at any stage of the production cycle.

- It ensures a high level of quality.It ensures a high level of quality.

- It is more economical.

- It produces written proof of any defects.

6 Pills of Curiosity: Did You Know?

In 1895, physicist Wilhelm Conrad Röntgen discovered X-rays and their properties (although he only announced this in January 1896), thus introducing the concept of radiography.

Where does the name X-rays come from? Röntgen achieved these results entirely by chance and, finding himself facing this phenomenon unexpectedly, he named it X, because it was unknown until then.

The first radiograph for a surgical intervention was made in 1896, a very short time after their discovery.

Among the various fields where radiographs can be used, besides the medical and industrial ones, there is also the artistic field: through the use of X-rays, digital images of paintings can be obtained.

It is thanks to scholar Marie Curie that the first mobile radiology services were established, introduced at the end of October 1914 and used as portable diagnostic tools during World War I to assist wounded soldiers.

The scanners for suitcases at airports work with X-rays and color objects differently based on the material they are made of, recognizing them by their density.

COMMENTS / 0